MIM Parts Supplier

MIM Parts Supplier

Blog Article

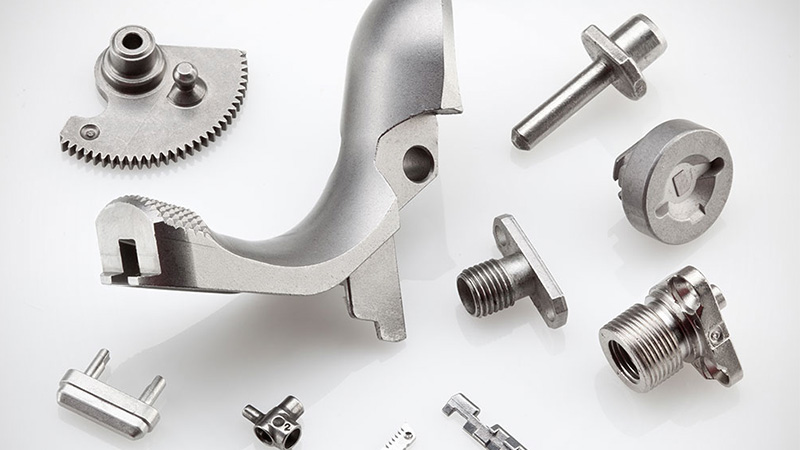

MIM (Metal Injection Molding) is an advanced metal parts manufacturing technology that combines powder metallurgy with plastic Injection Molding. It is suitable for manufacturing small metal parts with high precision and complex shapes. As a professional MIM parts supplier, Fair Shine provides complete processing equipment and assembly services, which are widely used in multiple industries.

MIM processing equipment and process

Fair Shine has a full set of MIM production equipment, including:

Injection molding machine: used to mix metal powder with binder for high-pressure injection molding.

Degreasing furnace: removes binder through solvent or catalytic method to give the parts initial strength.

Sintering furnace: sintering at high temperature to combine metal particles and improve the density and mechanical properties of parts.

CNC processing equipment: suitable for secondary finishing to ensure higher precision requirements.

Detection equipment: including three-coordinate measuring machine, X-ray detection, metallographic microscope, etc. to ensure product quality.

MIM process flow:

Raw material preparation: evenly mix metal powder and binder to form feed.

Injection molding: use injection molding machine to inject feed into the mold to form blank.

Degreasing: remove part or all of the binder to give the blank a certain porosity.

Sintering: sinter at a temperature close to the melting point of the metal to densify the parts and obtain the final shape.

Post-processing (if necessary): such as CNC finishing, heat treatment, electroplating, etc., to further optimize performance and surface quality.

MIM applicable materials

MIM process can be applied to a variety of metal materials, including but not limited to:

Stainless steel (316L, 17-4PH): high corrosion resistance, suitable for medical, electronic and precision instrument industries.

Low alloy steel: has excellent mechanical properties and can be used in automobiles, tools and other fields.

Titanium alloy: lightweight, high strength, widely used in aerospace and medical implants.

Tungsten alloy: high density, wear resistance, suitable for high-precision machinery and military applications.

Precision and surface treatment

MIM technology can achieve high precision of ±0.3% to ±0.5%, and can achieve stricter tolerance requirements through subsequent processing. Common surface treatment methods include:

Polishing: improve surface finish, suitable for high-end consumer electronics.

Electroplating (nickel, chromium, etc.): enhance corrosion resistance and improve appearance quality.

PVD coating: increase wear resistance and aesthetics, such as for knives or luxury goods.

Oxidation treatment: improve the corrosion resistance of metal surfaces, such as for industrial parts.

Features and application optimization of MIM parts

MIM parts have the following advantages over traditional processing methods:

Complex shapes: complex geometric structures that are difficult to achieve with traditional machining, such as internal hollow or tiny gears, can be manufactured.

High material utilization: powder molding reduces waste and improves production efficiency.

Batch production economy: suitable for mass production and reduces unit cost.

Excellent mechanical properties: compared with powder metallurgy, the density of MIM products can reach More than 98%, and the mechanical properties are close to forgings.

MIM products are widely used in:

Medical devices: dental braces, surgical instruments, minimally invasive surgical tools, etc.

Consumer electronics: smart phone parts, headphone parts, smart wearable devices.

Automotive industry: turbocharger parts, fuel nozzles, transmission system parts.

Aerospace: lightweight structural parts, high-strength fasteners.

Precision instruments: watch parts, optical instrument accessories, micro gear systems.

As a professional MIM parts supplier, Fair Shine is committed to providing high-precision, high-performance metal parts for various industries with advanced manufacturing equipment, strict quality control and comprehensive assembly services. The wide application of MIM technology has made it an indispensable part of modern manufacturing, bringing customers more efficient and economical production Solutions.