PEM Self Clinching Nut

PEM Self Clinching Nut

Blog Article

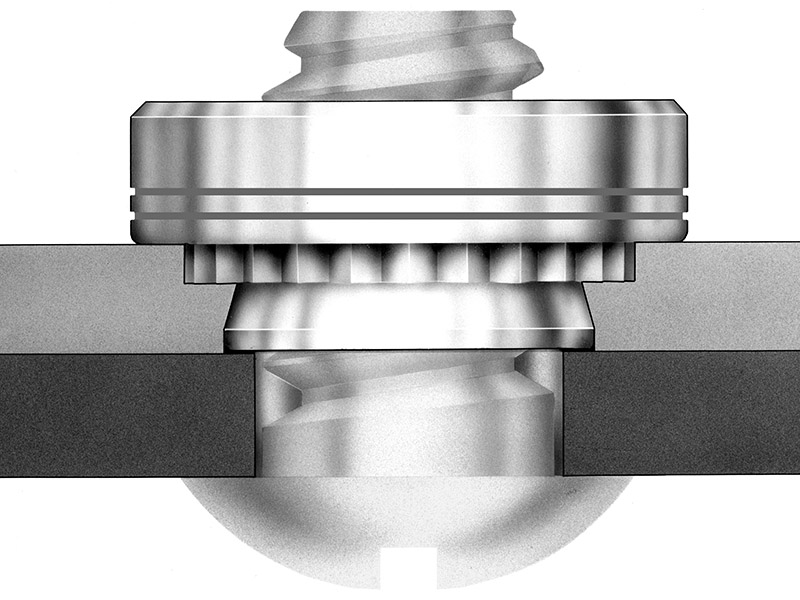

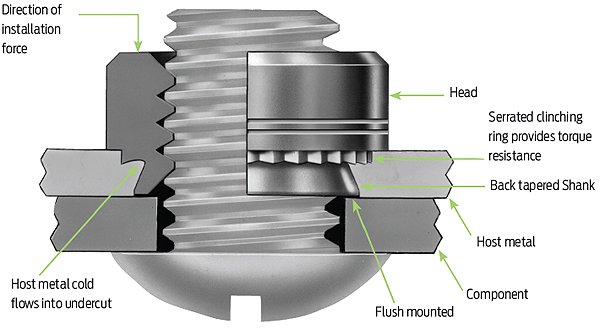

PEM self-clinching nut is a fastener designed for thin metal plates. The nut is embedded in the metal plate by cold pressing to form a reliable threaded connection. It can provide high-strength threaded connection on thinner plates, avoiding material damage or installation complexity problems that may be caused by traditional welded nuts or riveted nuts.

Material selection

The material selection of PEM self-clinching nuts mainly depends on the application environment and strength requirements. Common materials include:

Carbon steel (galvanized/nickel-plated): suitable for general metal plates, low cost, moderate strength, suitable for most industrial applications.

Stainless steel (SUS304, SUS316): Strong corrosion resistance, suitable for special environments such as high humidity, high temperature, chemical industry, such as medical, food processing and marine engineering.

Aluminum alloy: suitable for industries with high weight requirements, such as aerospace and precision electronic equipment, which can reduce overall weight and maintain good structural strength.

Features of PEM self-clinching nuts

Low plate thickness applicability: can be used for metal sheets above 0.5mm, providing high-strength threaded connection.

No welding required: cold pressing is used to install, avoiding the influence of thermal stress of welding.

Automated installation support: suitable for mass production, can be used in automated assembly lines, and improve production efficiency.

Anti-loosening design: after embedding, a reliable threaded connection is formed, which is resistant to vibration and not easy to loosen.

High durability: after embedding, it becomes part of the sheet and will not fall off after long-term use.

Advantages of PEM self-locking nuts

High-strength connection

Through plastic deformation, the metal sheet surrounds the embossed part of the nut, making it firmly fixed and providing strong pull-out and torque resistance.

Applicable to ultra-thin sheets

Traditional welding nuts are prone to welding deformation or penetration on thin plates. PEM nuts can form high-strength connections on extremely thin plates and are widely used in precision equipment.

Easy installation

The cold pressing embedding method is adopted, and no additional tools or welding equipment are required, which reduces labor costs and improves assembly efficiency.

Strong corrosion resistance

After using stainless steel or surface protection treatment, it can adapt to harsh environments such as humidity and chemical corrosion, ensuring long-term and stable use.

Lightweight design

Applicable to automotive, aerospace and other fields, it can reduce the overall weight of the equipment while ensuring the connection strength.

Surface treatment

PEM self-locking nuts have various surface treatment methods, the main purpose of which is to improve corrosion resistance and mechanical properties:

Galvanizing: Improve corrosion resistance and prevent rust, commonly used in general industrial applications.

Nickel plating: Enhance oxidation resistance and improve wear resistance, suitable for high-precision equipment.

Dacromet coating: Has excellent salt spray corrosion resistance, suitable for automobiles, oceans and high humidity environments.

Phosphating: Provides good wear resistance and can be used as a base layer for paint or coating to improve adhesion.

Black oxidation treatment: Provides certain corrosion resistance while meeting specific appearance requirements, such as military equipment.

Mechanical performance requirements

Pulling resistance

Ensure that the nut will not fall off the metal plate under high load, and common specifications can withstand tensile forces of 50N to 500N or more.

Torque resistance

Sufficient anti-rotation ability must be provided to prevent the nut from rotating when tightening the bolt, usually requiring a torque of more than 10Nm.

Durability

After tens of thousands of loading and unloading, it still maintains stable thread connectivity, suitable for equipment that requires frequent maintenance.

Scope of use

Due to the high strength, durability and lightweight characteristics of PEM self-locking nuts, it is widely used in the following industries:

Electronic equipment

Suitable for PCB fixing, metal housing connection, etc., providing high-precision fastening solutions.

Automobile manufacturing

Self-locking nuts are used in body, engine bracket, battery box and other parts to improve seismic resistance and installation efficiency.

Aerospace

Fields that require lightweight and high-strength connections, such as cabin interiors, instrumentation equipment, etc.

Medical equipment

Use stainless steel or anti-corrosion materials to ensure long-term stable operation of equipment, such as surgical equipment, testing instruments, etc.

Communication equipment

Used for metal housing installation of 5G base stations, server cabinets, and optical fiber equipment to ensure long-term stable signal connection.

Rail transportation

High-speed trains and subway car connection components provide stable seismic fastening solutions.

Household appliances

Suitable for fastening of metal housing structural parts such as refrigerators, air conditioners, and washing machines.

PEM self-locking nut is an efficient and stable metal sheet fastener with high strength, corrosion resistance and easy installation. It can be made of carbon steel, stainless steel or aluminum alloy, and can be enhanced by surface treatment such as galvanizing, nickel plating, Dacromet, etc. It is widely used in electronic equipment, automobile, aerospace, medical equipment and other industries to provide stable threaded connection for thin plates. It is an indispensable and important fastener in modern manufacturing.